The term “inclusive” stands for allowing diversity and engaging all people equally and interactively in a project. For me, when designing an inclusive workspace, the focus is therefore more on possibility than on impossibility. This involves searching for the smallest common denominator—for example, access through different senses: visually, but also haptically, or perhaps even through smell. Ideally, this inclusive approach is subtle and not immediately obvious, avoiding the risk of creating a new form of exclusion.

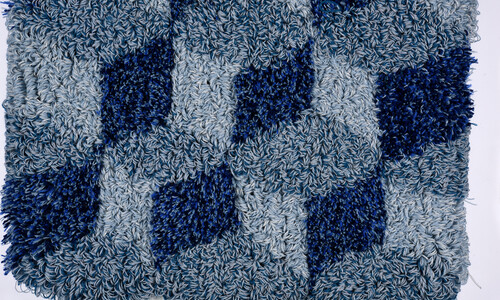

The design consists of a semi-permeable curtain that both encloses and creates spaces through the material itself as well as the variable construction of the surface. Raw wool is used—specifically, the waste wool generated during shearing from Brandenburg sheep, i.e., regional sheep. The wool is cleaned and combed into longer strands that bind the fibers together. The lanolin remaining after shearing gives the material its antibacterial, flame-retardant, and dirt-repellent properties, making the wool suitable for public spaces. The process continues with dyeing the fibers. By using environmentally friendly cold dyes and natural colorants, the wool retains its original warm, soft character. Finally, the strands are incorporated into a reversible interlacing of the knitted chain structure.

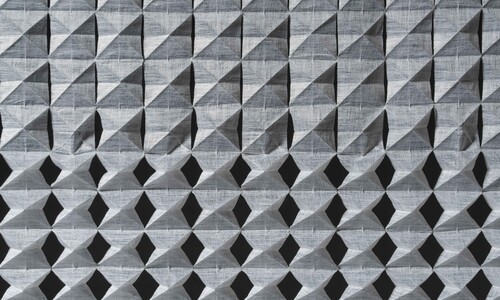

A special characteristic of this surface construction is the combination of softness and structural stability. The loops can be combined in different scales and with varying strand thicknesses, generating areas that are partially open or closed. Additional surfaces are made from industrially produced natural fibers or from sailing rope. The natural fiber offers a higher degree of transparency, while the sailing rope, with its high tensile strength, could be used to tension a railing. The laying of the loops is a craft process that should ideally take place on site, with the participation of the co-workers, so that the surface is integrated directly into the space.