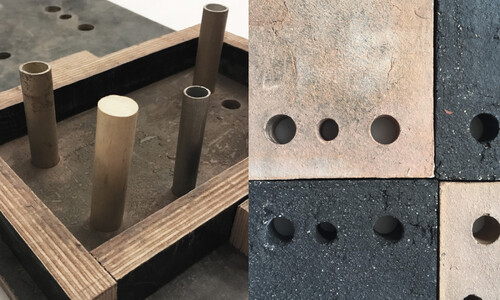

The 3D-printed bricks Maximiliana follow the concept of working exclusively with natural materials. The name belongs to a close relative of mine who was a farmer and always reminded me of the direct work with earth.

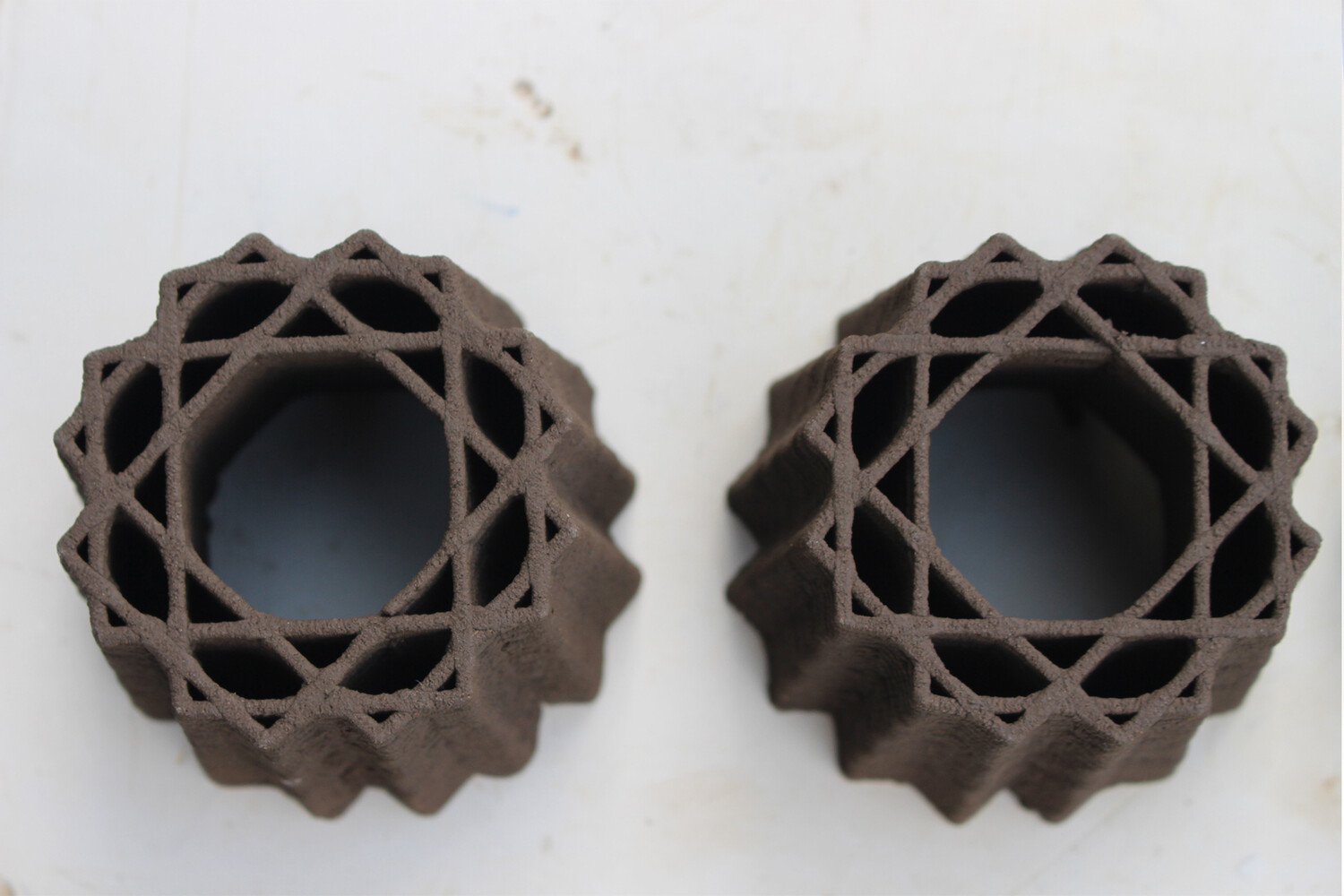

Maximiliana is the result of processing natural clay from Sauen in Brandenburg, which, in combination with a biomaterial (aloe-agave juice), was made more plastic and specifically developed for use in ceramic 3D printing.

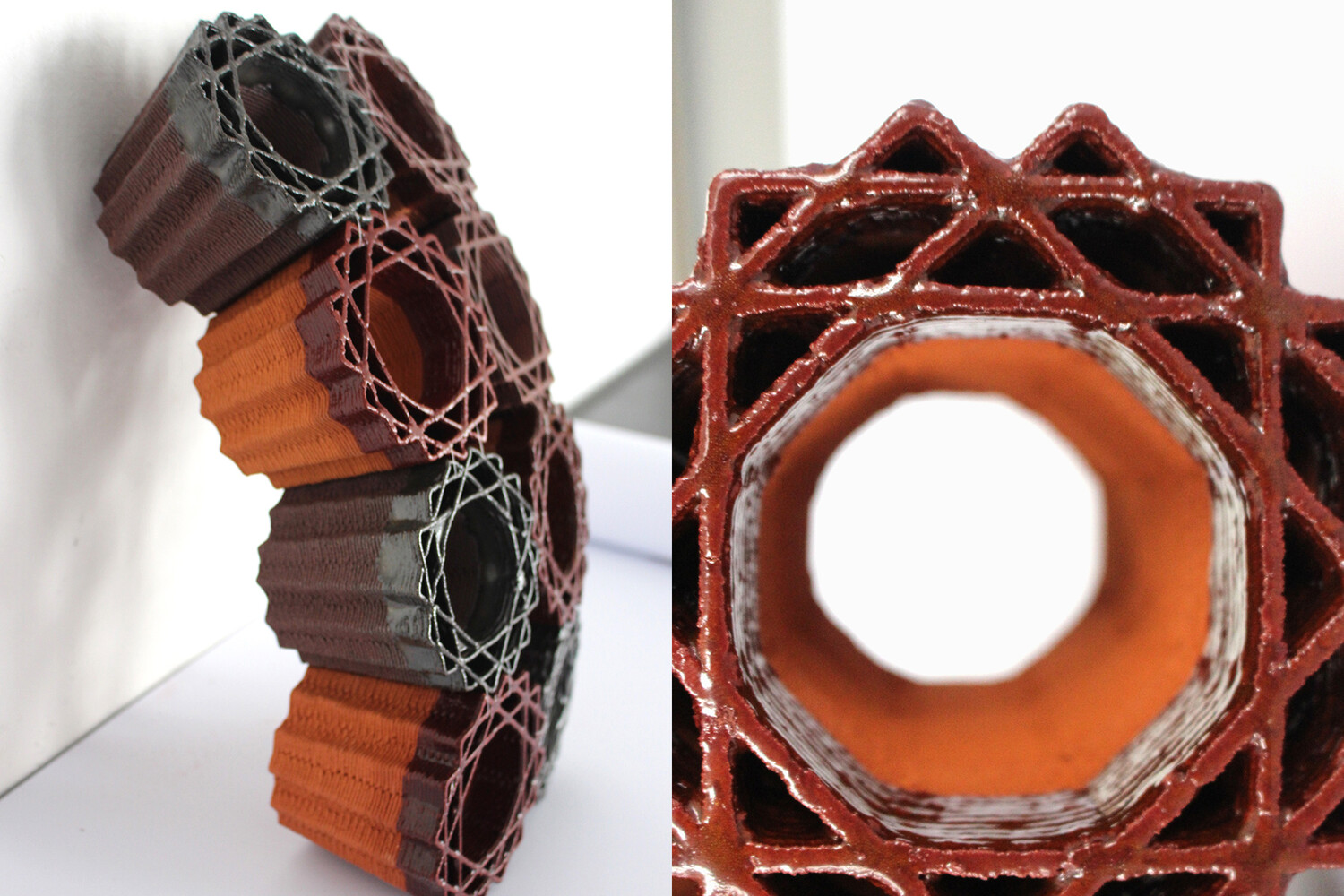

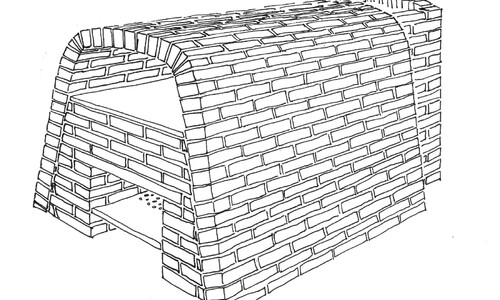

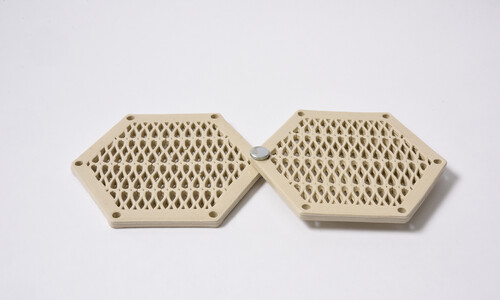

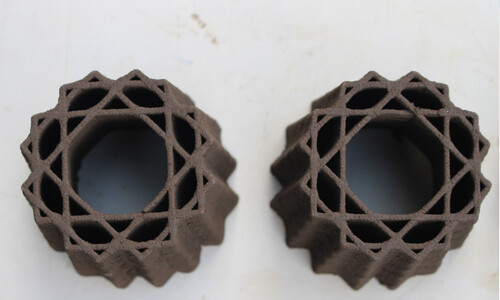

This opens up the possibility of creating new ceramic forms with complex geometric elements that can be used both indoors and outdoors, serving as a bridge between architecture and traditional earthen construction. The idea is to elevate classic bricks to a new design level through the use of modern technology. The uniqueness of each object lies precisely in this interplay between traditional craftsmanship and the creative possibilities of digital tools.

The combination of digital technology and clay optimized with plant-based material results in a special relationship between material and form: the composition of the clay allows the production of complex geometries with unusually high stability even in the unfired state.

The shape of each brick is slightly conical, tapering toward the end. This allows the bricks to be assembled into curved or even wave-like forms.

The basic form of Maximiliana is derived from the abstraction of a decorative rosette from the hats of women in the Peruvian mountains, which indicates their marital status.